Technology is advancing at a rapid pace.

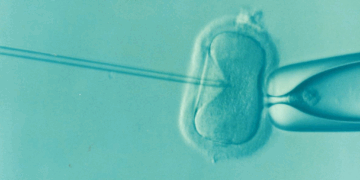

Scientists are on the brink of perfecting a bioengineered, 3D-printed human ear that closely mimics the appearance, texture, and durability of a natural ear, offering hope for individuals with congenital ear deformities or those who have experienced ear loss or damage due to injury. This groundbreaking development, led by a team at Weill Cornell Medicine in New York City, holds tremendous potential to revolutionize ear reconstruction procedures, which currently involve multiple surgeries and intricate craftsmanship.

Dr. Jason Spector, the senior author of the study and a surgery professor at Weill Cornell, underscores the transformative impact of this technology in providing realistic solutions for correcting outer ear abnormalities. Unlike traditional methods that rely on a child’s own rib tissue for ear reconstruction—a procedure that can be painful and result in scarring—the bioengineered ear promises to deliver both aesthetic and functional fidelity to the natural ear.

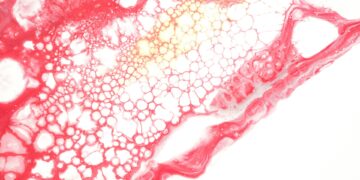

The key lies in harnessing chondrocytes, the cells responsible for cartilage formation. Previous attempts using animal-derived chondrocytes embedded in collagen scaffolds fell short of replicating the intricate structure and flexibility of the ear due to tissue contraction. Undeterred, the research team devised a new approach, starting with a precisely crafted plastic scaffold resembling the human ear, produced using 3D printing technology.

Sterilized animal-derived cartilage was then carefully layered onto this scaffold, ensuring compatibility to prevent immune rejection. Over a period of three to six months, the cartilage gradually integrated with the scaffold, resulting in a structure that closely resembled the natural contours of the ear. Biomechanical testing confirmed that the engineered cartilage exhibited flexibility and elasticity similar to natural ears, albeit with some durability concerns.

To address this limitation, the researchers propose incorporating recipient-specific chondrocytes, potentially sourced from undamaged ear tissue, to enhance the replacement ear’s biomechanical properties. This personalized approach holds promise for further refining the bioengineered ear, bringing it closer to achieving parity with its natural counterpart in both form and function.

Discussion about this post